If you run a production or packaging line and are working on improving business results, we can help.

Who We Are

Our team is a talented mix of electrical, mechanical, and software engineers combined with operations and maintenance managers, automation specialists, data scientists, and other smart folks.

Our team excels at understanding the interconnecting implications of people, machines, technology, and process. We have a track record of success in delivering extraordinary results on multifaceted projects.

We use automation, process engineering, industry 4.0 technologies and data to:

- Maximize throughput on your lines

- Address labor availability issues and reduce costs

- Automate processes to eliminate human errors

- Collect accurate, timely data

- Leverage data to optimize operations

What We Do

Operational Efficiency Improvements

Performance improvement with fast payback is our foundational passion. Every environment we work in has achieved significant throughput increases with a fast ROI. With everything we offer, increased throughput comes with it.

Solve Labor Availability

Issues Line improvements focused on labor availability issues results in simpler tasks, happier workers, and reduced labor costs.

Industry 4.0 feasibility study and evaluation

The fourth revolution is happening and we’re ready, are you? Let us assess where your operations are positioned, and define the path to Industry 4.0

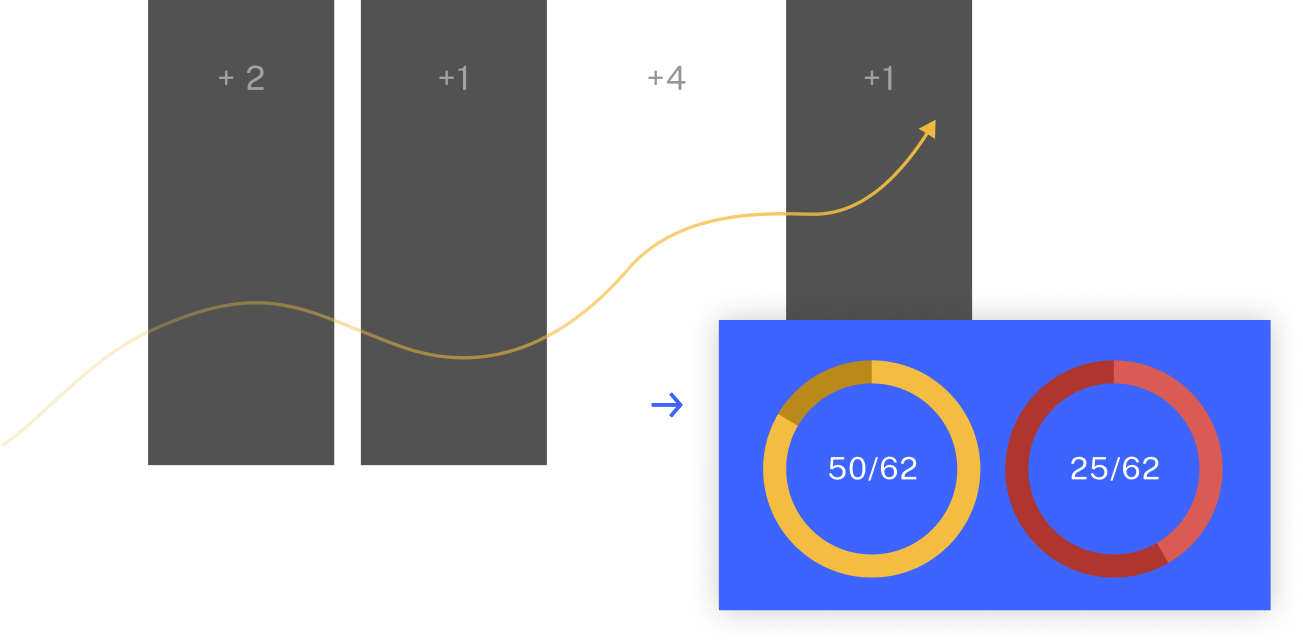

Business Intelligence (BI) for your Operation

Automated data collection and reporting is at the heart of what we do. Designing department specific dashboards and reporting mechanisms is second nature to us. No writing, no typing, no human errors. Straight from the production floor in real-time.

Automation - Control System Design and Implementation

From greenfield facility design to existing process refinement, operations expertise is critical to our business success. Let us show you why we’re so much more than integrators.

MES-to-ERP Link with the Right Data

ERP Systems are data reliant. The accuracy and efficiency of data transfer from production to the ERP is critical. Our operations experience ensures the right data is collected automatically and transferred to your ERP with no manual effort. While automatically collecting the right data, our process simultaneously increases throughput. on the line.

PLC and HMI Programming and Commissioning

By understanding the capabilities of equipment and line performance, we’ll get your equipment running effectively as soon as possible.

AutoCAD and Solidworks 2D and 3D models

Most great ideas start with a conversation. Let us produce the models to turn ideas into reality.

Quality and Traceability

With today's fast changing regulatory framework, Lyne Systems has created solutions to automatically enforce quality protocols such as HACCP, SFCR, and FSMA. Our extensive data collection enables immediate traceability findings all the way from supply to customer, without the need for any worker inputs.