Production Optimization

For Packaging, Production, and Processing Lines Significantly improve throughput on lines.

Redefine What is Possible

Lyne Systems doesn’t just improve your line - we maximize it. We are the experts in process design and controls to monitor, record and optimize the flow of product on your production line.

Our Production Optimization System:

01

Increases the capacity and reliability of line throughput

02

Eliminates human errors

03

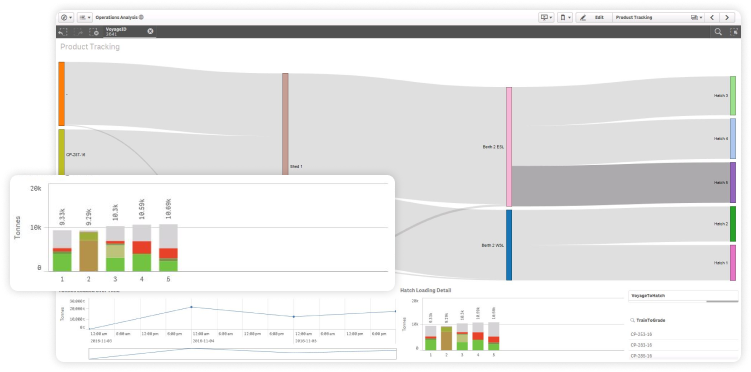

Provides complete product traceability & transparency

04

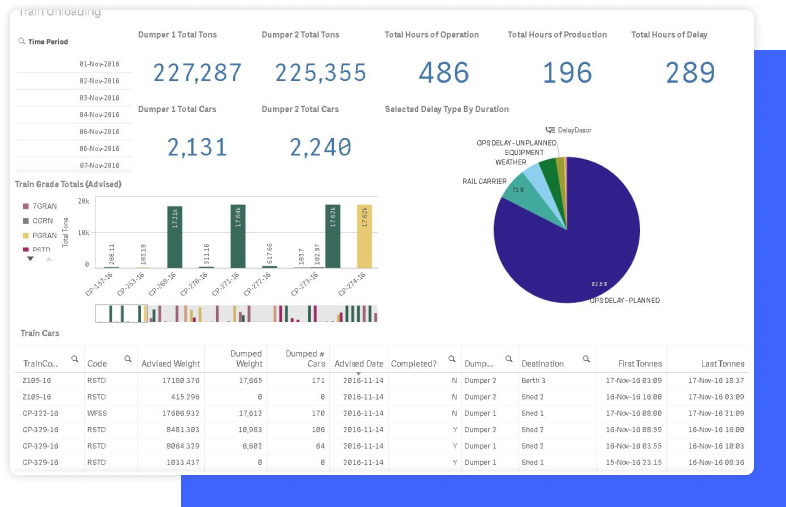

Provides real-time reporting for executive decision makers

The Difference Between Improved Performance

and Optimum Performance

Beyond simple start-and-stop line integration, we measure and analyze line data, then use complex algorithms and controls to keep the production line running consistently at maximum throughput. This approach allows us to achieve significant throughput increases on every line we optimize.

A better line is a better bottom line

Lyne Systems enables your production operations to do more with less, drive down costs, and flow more revenue to the bottom line. Using sophisticated controls and the accurate production data they generate, Lyne Systems lets you move from ‘gut-feel’ to data-driven decision making.

- Gain more control over the complexity of operations

- Drive a cycle of continuous improvement

- Optimize the use of available labour

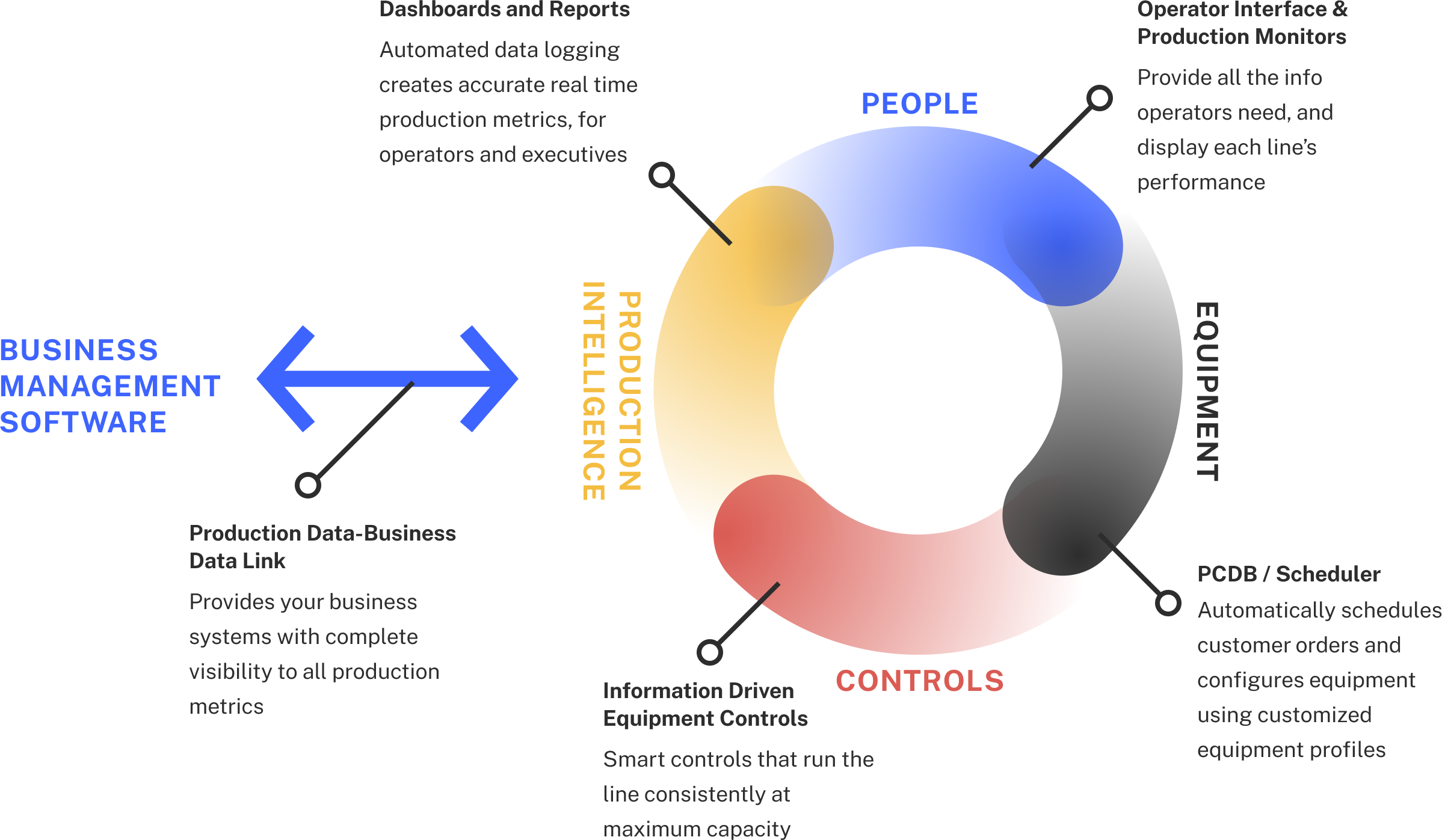

Our Production Optimization System includes:

01

Assessments and Design

A Lyne expert will visit your facility to conduct a preliminary assessment of your facility’s existing equipment and capabilities. Efficiency and labor optimization opportunities will be identified, and our team will follow up with an improvement estimate with an ROI of under 1 year.

02

Mechanical modifications

After review of existing equipment and line performance, it is common that minor mechanical modifications will significantly improve throughput and quality. These modifications combined with our controls upgrades regularly provide the same or better improvement than the purchase of new equipment.

03

Information Driven Equipment Controls

Lyne Systems goes beyond line integration to provide smart controls that are focussed on throughput optimization. While others may focus on line integration that can start and stop equipment at the same time, we ensure that the entire line is running consistently at maximum throughput.

04

Data Collection Infrastructure / Sensing

Our experts have an intimate knowledge of production environments, and understand all the right data that needs to be collected in order to support workers, operators, and line performance. If your existing equipment is unable to measure this data, we will install additional sensors and cameras to ensure we are getting every piece of the puzzle to make your line run consistently at maximum capacity.

05

Streamlined Operator Interfaces and Production Monitors

Operator interfaces are designed to provide operators with all the information they need, and nothing they don’t need to run the line effectively. Smart alarms and messaging show Operators what’s happening and what actions to take to resolve issues. Where possible, Operator decision making is automated to immediately resolve production issues. In the facility, production monitors clearly display line status and performance metrics to all workers and supervisors.